SMR In/Out System

Features

- Supports 3D / 2D digital twin platforms.

- Solves the problem of shortage in on-site supervisors.

- Solves cross-border / cross-factory management immediacy and saves travel costs.

- Real-time elimination of abnormalities.

Function Description / Benefits

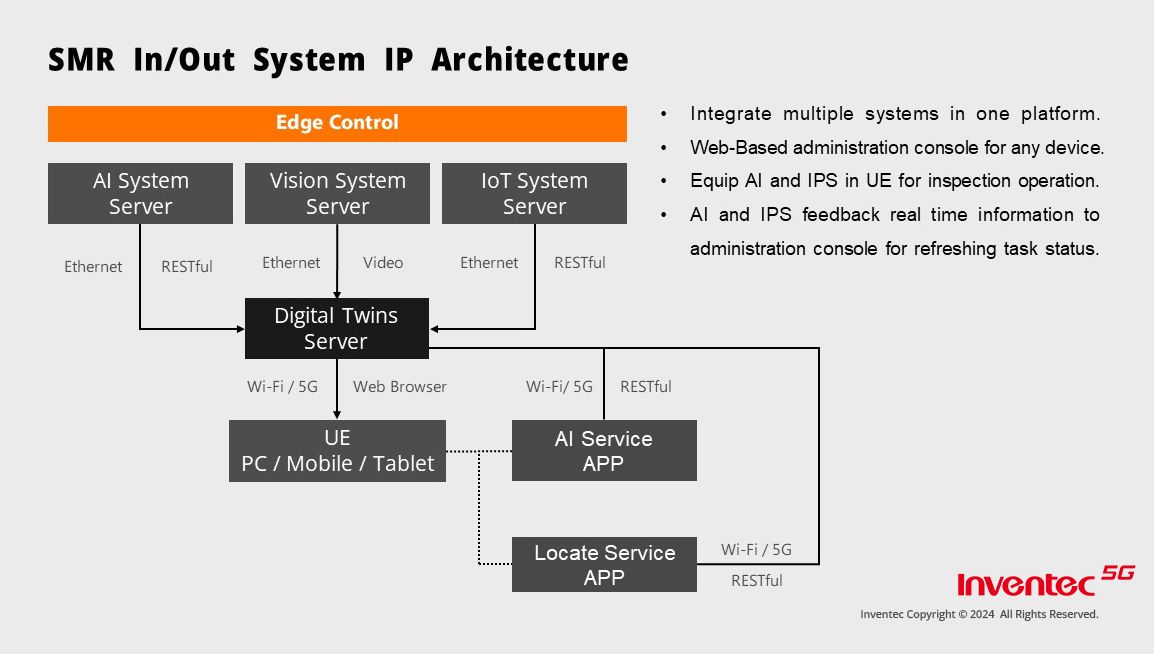

Architecture

|

The plant management module provides plant and production line management flexibility. By simulating real situations through virtual production lines in combination with work order information and on-site environmental information, and analyzing the operation information of production equipment through AIoT in real-time, equipment monitoring and abnormality detection are automated. Important information is pushed actively to help managers make decisions and task commands, and choose to play the real-time on-site situation of specific workstations. The integration of virtuality and reality strengthens the real-time dynamic management of managers and achieves the following benefits.

|