|

Metal Surface Engraving AI Detection Solution

Pain Points Solution Advantages

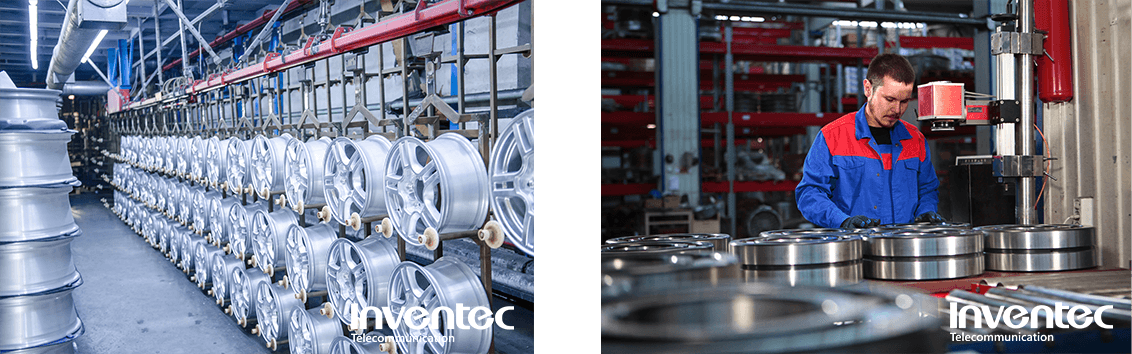

The Metal Industry Surface Engraving AI Inspection Solution focuses on various inspection technologies such as "graphic and text engraving quality and position correction." By integrating AI inspection solutions with automated production line equipment, it provides precise and efficient solutions. This solution is suitable for production scenarios with small-batch, diverse product combinations, enhancing quality control efficiency and reducing the management costs associated with quality anomalies.

Pain Points in the Metal Industry

- Manual Inspection Efficiency Is Challenging

Manual inspection is difficult to maintain stable accuracy due to differences in the experience and abilities of quality control personnel which makes it difficult to maintain stable and accurate detection rates. In large-scale production, to maintain a high yield rate, more quality control staff must be employed, increasing overall production costs, management complexity, training, and auditing challenges.

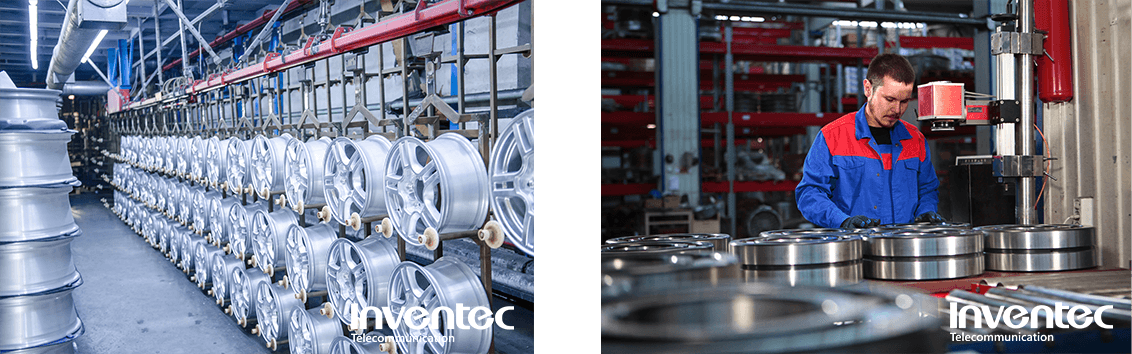

- Metal Reflection and Curved Surface Increase Difficulty in Automation Inspection

The demand for automation in the metal industry is continuously increasing. However, the high gloss, reflectivity, and curved surfaces of the products present significant challenges for automated inspection. Under the harsh conditions of high-gloss, reflective, and curved surfaces, it is necessary to rely on an experienced team to integrate AI inspection models, imaging equipment, and lighting environments in order to achieve stable and reliable inspection results.

- In response to the inefficiency of automated inspection for small-batch, diverse product combinations

The small-batch, diverse product mix results in poor efficiency in establishing inspection samples for automation. By using AI inspection solution, the need for defect samples can be significantly reduced, and the implementation timeline can be shortened.

- Traceability and Integration Difficulty across Production Stations

Lack of effective integration of inspection equipment across different production line stations leads to management gaps, lowering production efficiency and negatively impacting the overall supply chain operations.

Solution

- Full Automation Detection across Stations

In diverse production environments, from product identification and inspection item confirmation to AI inspection of surface engraving quality and position, all processes are seamlessly integrated. This ensures effective error correction, ensuring the product meets high-quality standards.

- "Intelligent" Automated NG Defective Product Diverting

The system can immediately detect abnormal products, alert operators in real-time, and automatically divert them via an "NG Outlet" ensuring smooth production line operation and reducing issues like WIP (Work In Progress), labor hours, and manual intervention.

- Customized Lighting Source Technology

A lighting environment is designed specifically for the reflective characteristics of metal products. After obtaining stable and clear inspection images, they are processed by an optimized AI inspection model for inference, making it suitable for a variety of metal products.

- Real-Time Monitoring and Abnormality Analysis

The Edge AI architecture is capable of adapting to the production cycle time on the production line, reducing the AI detection response time and immediately recording any inspection anomalies. This is helpful for tracing back through previous processes to identify the root cause, such as tool breakage or incorrect work order scanning.

- Customizable and Multi-Station Integration Design

The lighting environment and imaging equipment are designed based on constraints such as the customer's product mix, production line layout, and production cycle time. The AI inspection model is optimized, and customized inspection parameters are adjusted to achieve the best inspection results. With multi-station integration capabilities, the system provides full-process inspection from the initial station to the final processing, meeting diverse production requirements.

Solution Advantages

- Highly Integrated and Flexible Application

The AI inspection system integrates industrial-grade imaging equipment, custom lighting sources, and Edge AI inspection devices to form an end-to-end automated inspection system. The customized management platform can flexibly interface with existing production management systems, meeting the diverse needs of metal processing plants with small-batch, varied product combinations.

- Real-Time Data Monitoring and Traceability

Supporting Edge AI technology, the system records and analyzes detection anomalies in real time, helping quickly identify the root cause of issues and improving production efficiency.

- Significant Improvement in Detection Efficiency and Accuracy

The on-line and off-line inspection solutions use high-speed detection design, combined with a multi-station inspection layout, effectively enhancing the overall operational efficiency of the production line.

|