|

Inventec uses its Digital Twins and Intelligent Inspection solutions, introduces AI Smart Detection, IPS, Task Arrangement and Plant Management, supports highly efficient control, check and maintenance mechanism of production line, saves time and reduces human error for operators during task allocation, check and maintenance.

AI Smart Detection.

Runs AI Inference on tablet or edge device to identify and analyze data. Staff operating the Digital Twins will feel like they are on the spot through this interface. AI can identify defects such as flaw, discoloration and physical damage automatically. Barcode reading can realize digital maintenance and management, save maintenance time and reduce human error.

IPS.

This module uses IPS (Indoor Positioning System) to track movement of workers and equipment, and guide staff to the work area destinations to perform inspection or maintenance. If the worker or equipment goes the wrong way, the operator of Digital Twins will be notified.

Task Arrangement.

Support automatic allocation of work area and inspection target. The event log integrates inspection results and time. When the inspector reaches the checkpoint, the virtual dashboard of the tablet or AR equipment pops up the system window.

Plant Management.

Use the Digital Twins to manage the entire assembly line and simplify dynamic deployment. The Digital Twins shows the current condition of production line to switch lines conveniently and reduce production downtime.

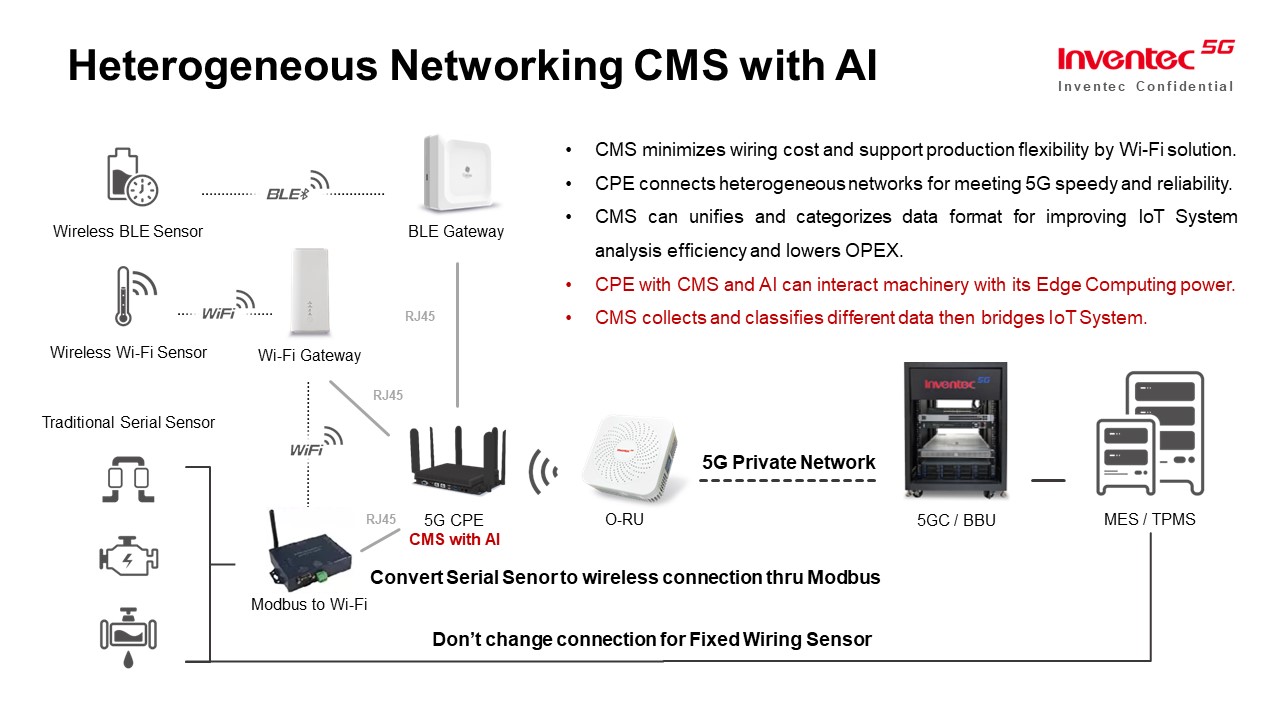

To deploy CT, besides using 5G O-RAN distributed establishment, indoor ISC(Integrated Small Cell)can also be used. The feature of ISC is that CU, DU and RU are integrated to one host. This structure connects the terminal device to the Indoor ISC via 5G. It connects the 5G Core Network by fiber optics and combines with the IT online service application to form the private 5G network service. This structure helps realize high cost-performance for fields with small range and clear application objective.

To realize the Digital Twins and Intelligent Inspection, 5G Edge AI Gateway(NX-H3003)uses outstanding AI edge computing ability and heterogeneous network integration ability for the sensing equipment of production line to perform edge computing via NX-H3003 to achieve real-time computing and reinforce management outcome.

|