|

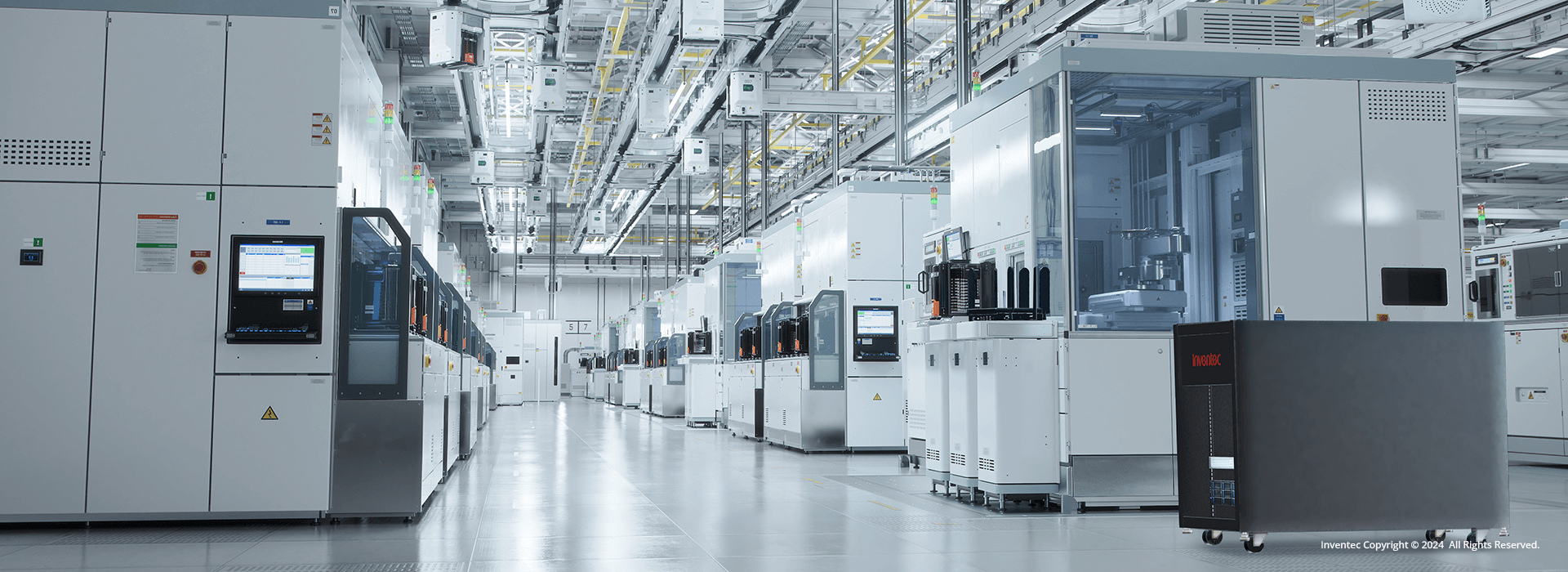

OEE, Security and Safety Improvement.

There are tens of thousands of equipment or sensors on one floor. In factory management of the semiconductor industry, precision process demands a high level of signal interruption prevention. There were lots of restrictions on physical network deployment, such as inflexible wiring location, long wiring time, high labor cost, construction safety problem due to frequent entry to factory, occupational safety maintenance, high cost of equipment maintenance and repair.

With regard to the management requirement for smart factory, high cybersecurity requirement for private network, risk control, such as movement, guidance and positioning of contractor in the factory, and occupational safety protection management, the cost of labor and material resource used to be high.

|

|

High cybersecurity level integration of the heterogeneous network supports the critical management demand in semiconductor smart factory.

- Simplify the network structure via integration of heterogeneous network saves the time, space and cost for deployment. Besides solving network fragmentation problems, current system and application of customer have been integrated as well.

- High level of cybersecurity control is implemented. Illegal equipment, such as an unauthorized 5G terminal device, cannot connect to the private network once the SIM card is replaced.

- Voluntary protection is executed. By using an AI occupational safety protection system, identify of staff can be controlled and identified, and it is also possible to identify whether or not a construction worker in a dangerous area is fully equipped with safety equipment.

- Wireless smart devices, such as Bluetooth watch and smart phone, send alarm to CCR, and send a report immediately upon the incident to handle the incident quickly, and reduce damage and risk.

- Human is the most uncontrollable factor in the environment. Through the Intelligent Inspection and Tracking program, the contractor can wear the smart watch or portable tablet to complete SOP requirements by following the task route and guidance.

CMS monitors production, quality and the health condition of equipment. This helps accomplish the ESG goal besides enhancing OEE.

|